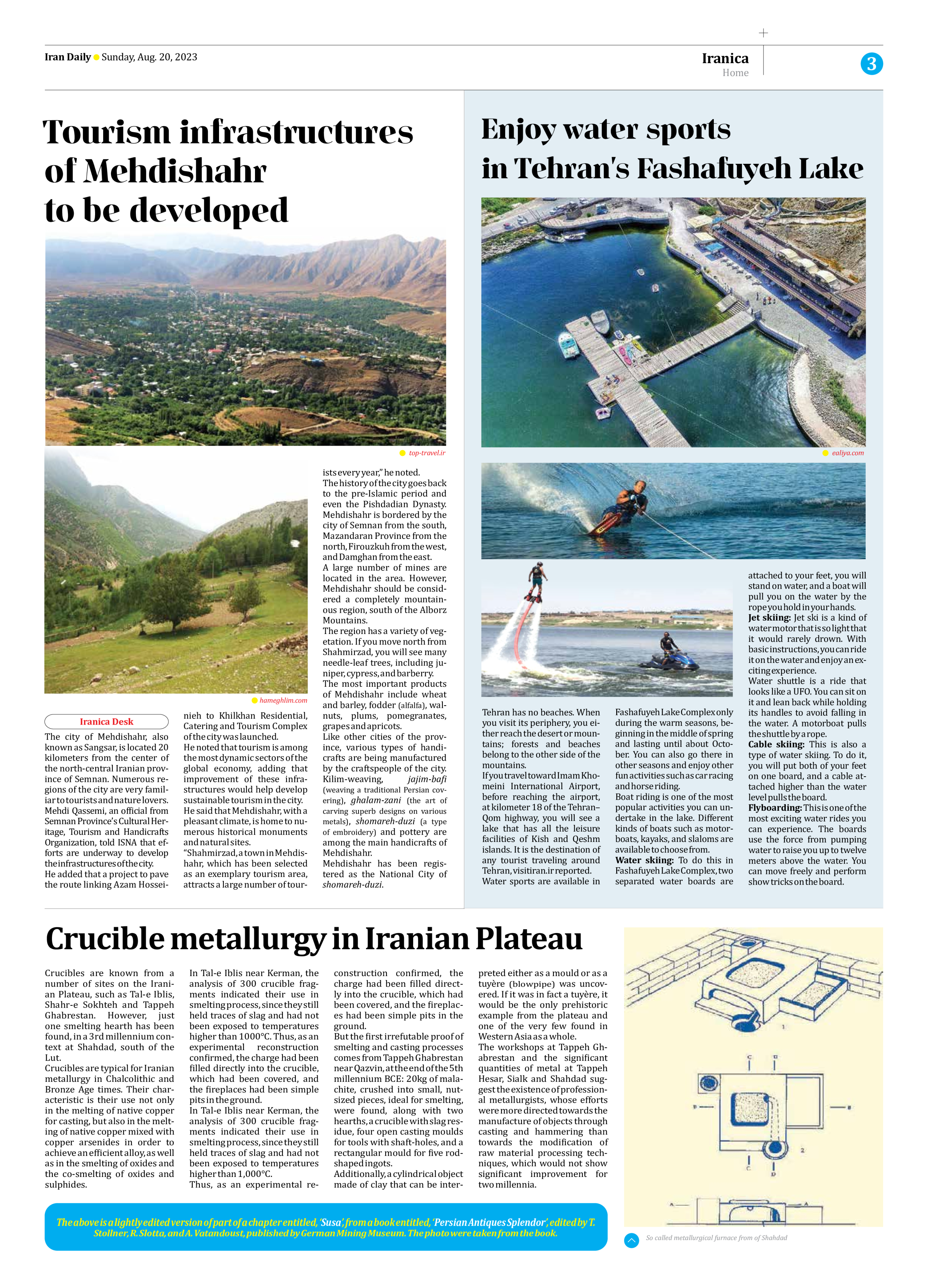

Crucible metallurgy in Iranian Plateau

Crucibles are known from a number of sites on the Iranian Plateau, such as Tal-e Iblis, Shahr-e Sokhteh and Tappeh Ghabrestan. However, just one smelting hearth has been found, in a 3rd millennium context at Shahdad, south of the Lut.

Crucibles are typical for Iranian metallurgy in Chalcolithic and Bronze Age times. Their characteristic is their use not only in the melting of native copper for casting, but also in the melting of native copper mixed with copper arsenides in order to achieve an efficient alloy, as well as in the smelting of oxides and the co-smelting of oxides and sulphides.

In Tal-e Iblis near Kerman, the analysis of 300 crucible fragments indicated their use in smelting process, since they still held traces of slag and had not been exposed to temperatures higher than 1000°C. Thus, as an experimental reconstruction confirmed, the charge had been filled directly into the crucible, which had been covered, and the fireplaces had been simple pits in the ground.

In Tal-e Iblis near Kerman, the analysis of 300 crucible fragments indicated their use in smelting process, since they still held traces of slag and had not been exposed to temperatures higher than 1,000°C.

Thus, as an experimental reconstruction confirmed, the charge had been filled directly into the crucible, which had been covered, and the fireplaces had been simple pits in the ground.

But the first irrefutable proof of smelting and casting processes comes from Tappeh Ghabrestan near Qazvin, at the end of the 5th millennium BCE: 20kg of malachite, crushed into small, nut-sized pieces, ideal for smelting, were found, along with two hearths, a crucible with slag residue, four open casting moulds for tools with shaft-holes, and a rectangular mould for five rod-shaped ingots.

Additionally, a cylindrical object made of clay that can be interpreted either as a mould or as a tuyère (blowpipe) was uncovered. If it was in fact a tuyère, it would be the only prehistoric example from the plateau and one of the very few found in Western Asia as a whole.

The workshops at Tappeh Ghabrestan and the significant quantities of metal at Tappeh Hesar, Sialk and Shahdad suggest the existence of professional metallurgists, whose efforts were more directed towards the manufacture of objects through casting and hammering than towards the modification of raw material processing techniques, which would not show significant improvement for two millennia.

The above is a lightly edited version of part of a chapter entitled, ‘Susa’, from a book entitled, ‘Persian Antiques Splendor’, edited by T. Stollner, R. Slotta, and A. Vatandoust, published by German Mining Museum. The photo were taken from the book.